Sawmilling is an ancient craft that has become a cornerstone of modern industries, blending precision, expertise, and innovation. From providing essential lumber for construction to crafting fine wood products, sawmills play a pivotal role in supporting economies and meeting global demand for timber.

You may know Bendrey Brothers as your go-to supplier in Bristol for garden and other DIY materials, but did you know that we also have one of the only working sawmills in Bristol? We combine traditional craftsmanship with modern techniques, to produce high-quality timber products while remaining a hidden gem in the industry.

The Role of a Saw Mill

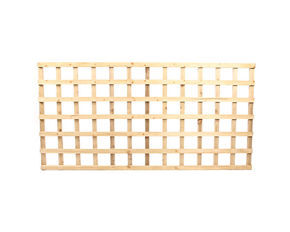

A sawmill is designed to process raw logs into usable lumber, including planks, timber cladding, beams, and timber boards. The process begins with sourcing timber, either from sustainably managed forests or reclaimed wood sources. Once the logs are transported to the mill, they undergo various stages of processing, including debarking, cutting, and drying.

Modern sawmills are equipped with advanced technology to enhance efficiency and minimise waste. Computerised systems measure logs to determine the most efficient cutting patterns, ensuring every piece of wood is used effectively. This precision is critical not only for maximising yield but also for meeting the stringent standards required for specific wood applications.

The Sawmilling Process

Log Selection and Preparation

The journey of sawmilling starts with log selection. High-quality wood is essential to producing strong, durable lumber. After selection, the logs are transported to the sawmill, where they are stripped of their bark.Cutting and Sizing

Cutting is the heart of sawmilling. Saws, ranging from large circular saws to band saws, slice the logs into rough lumber. The precision of this stage determines the dimensions and quality of the finished product. At Bendrey Brothers, we use cutting-edge machinery to ensure accuracy, allowing us to meet diverse customer needs.Drying and Treatment

Freshly cut wood contains significant moisture, which can lead to warping or decay if not treated. Kiln drying or air drying is used to reduce moisture content, stabilising the wood for various applications. Depending on its end use, the lumber may also undergo chemical treatment to resist pests and environmental damage.Grading and Packaging

Once processed, the lumber is graded based on its quality and intended use. Whether for structural purposes or fine woodworking, each piece is categorised to meet industry standards.

The Expertise Behind Sawmilling

Sawmilling requires more than just advanced machinery; it demands expertise, skill, and an eye for detail. Workers in a sawmill must understand the properties of different wood types, from hardwoods to softwoods. This knowledge allows them to tailor the sawing process to the unique characteristics of each log, ensuring optimal results.

Experienced sawmill operators also play a vital role in minimising waste. By carefully planning cuts and utilising offcuts for other purposes, such as wood chips or biomass fuel, they contribute to a more sustainable industry.

Bendrey Brothers: Bristol’s Best-Kept Secret

As a family-run sawmill in Bristol, Bendrey Brothers is a shining example of how traditional expertise and modern innovation coexist. While it may not be widely known, the sawmill has earned a loyal following for its dedication to producing high-quality lumber with precision and care.

We pride ourselves on sourcing timber responsibly and ensuring that our operations support environmental sustainability. By embracing efficient processing techniques and minimising waste, the company reduces its ecological footprint while maintaining competitive prices for its customers.

With years of experience and a passion for craftsmanship, our team ensures that every log is transformed into quality timber that meets the highest standards. From structural timbers to custom wood products, the company’s output reflects its commitment to excellence.

The Future of Sawmilling

As global demand for wood products continues to grow, sawmilling faces new challenges and opportunities. Innovations in technology, such as the role of AI in sawmilling and automated machinery, are making the industry more efficient than ever before. At the same time, there is a growing emphasis on sustainability, with sawmills adopting practices that prioritise forest regeneration and carbon neutrality.

We pride ourselves on being at the forefront of these trends, demonstrating how small, family-run businesses can compete with larger operations by focusing on quality, sustainability, and customer service. By staying ahead of industry changes while honouring traditional methods, they ensure their place in the future of sawmilling.

Conclusion

The craft of sawmilling is a testament to human ingenuity and adaptability. From the raw power of early water-driven mills to today’s exact and sustainable operations, the evolution of the sawmill reflects our ability to meet the changing needs of society.

Whether you’re an industry professional or simply someone who appreciates the beauty of wood, the story of sawmilling is one of craftsmanship and enduring relevance. If you want to know more about our Bristol sawmill, why not pay us a visit at our timber yard or get in touchwe’ll be happy to talk you through our process.